The premise is simple: after playing around with the existing timers on the market, we realized there was a significant trade-off afoot. Most timers were capable of satisfying the basic needs but did not actually offer any smart and interactive features. In our age, this is an immediate red flag for disruption, innovation, re-design, and UX gratification.

Our journey (not yet finished) towards the ultimate gym wall timer revealed a whole bunch of misconceptions, biases, and scarcities that it made me wonder:

How detached digital designers and developers are from the physical world of production, and where this detachment stems from.

Image credit: Devin Halladay

Product evolution or branching

At some point, all products used to be physical. The tangibility of a product used to come in direct relation with its value. Fair enough, you can see what it takes to make good stuff. You’ve tried it and you know how hard it is.

Therefore, craftsmen have always been appreciated and never unemployed.

At the same time, where there is a product, there is a service. Sometimes the service does not require a product, as the service itself can be as valuable as any product. If we do something, there is always someone who does it best and you don’t necessarily have to be ethical.

Therefore, prostitutes have always been appreciated and never unemployed.

The product-service relationship has been going hand-in-hand ever since we first started producing things exceeding our own personal need for them. Selling the surplus becomes a great option, in that case, eventually edging out the first purpose and producing only for sale.

With the development of technology and digital implications of physical products, we entered the domain of intangible values that are easier to grasp but much harder to build because we are dealing with an ethereal matter of internal perception. Early digital products had to earn their credibility through the resemblance of the physical ones, thus the design was skeuomorphic with a strong relation to the controls of the real products.

The evolution of physical products has always been propelled by the customers’ desire to explore the unknown opportunities, be flashier, and top the others by possessing certain things.

The pinnacle of this narcissistic chase resulted in the paradigm where the technology becomes a social status marker. In this case, digital product development is nothing but a branch of the tangible goods production where the more unique thing you own, the higher your success rate.

The seclusion of digital production

If we agree upon the fact that digital product development followed the path of physical production, it makes perfect sense that early software and web application development used the same approaches, instruments, and assets as tangible production. The go-to methodology was obviously the most natural one, the one used from the early days of craft economy – the stage-gate process or waterfall. Let’s take a look at the definition of product development:

“Product development is the process until a product can be used: starting with the product planning and the search for ideas, the definition of the product, respectively with the single part production: starting with the order up to the delivery of the product at the customer.” – Ehrlenspiel, 2003.

Within the stage-gate methodology, a product is developed incrementally through phases overlapping occasionally depending on the specifics of the product, the organization of the production, and resources. Typically the phases are:

- Product & customer research

- Planning

- Design and development

- Prototype testing

- Manufacturing and assembly

Due to the higher costs of resources, physical production relied heavily on the process of implementation, putting emphasis on the earlier stages and improving the production depending on the changes of the market. In that sense,

Product development is the conversion of market needs into a purchasable product.

As the result of such approach, a lot of early software developers with the mental framework of physical manufacturers suffered from the “reinvention of the wheel”, putting a lot of their efforts in the same production ideas as the rest of the competition. Ultimately, there is only one market we all cater to. The change happened when digital production gurus realized they are dealing with a different animal and require a different set of tools and methodologies.

The Agile effect

Scrum and Kanban became the early signs of Agile Product Development. The difference they were making was in the scale of effective planning. Building a physical product requires a great deal of planning due to the technological limitations, meaning you only have one shot at setting up your facility, otherwise you’ll have to rebuild the entire thing before you even get to the product.

Digital production is nowhere near that cost and is all about microplanning which makes your business model more susceptible to the changes of the market while the product is being designed.

While traditional development is all about minimizing the change in the course of the project by means of an extensive research before the actual development starts, Agile allows us to focus on adaptation and innovation rather than probability and control. With this concept, digital development skyrocketed and eventually entailed the hardware and physical product industry as digital technologies need something to run on.

It is worth mentioning, that with the advent of Agile, the new mindset also took shape. Before, any type of production had to be based on the academic research, scientific papers, and abstracts. Agile was created by the practitioners and was far more …well, agile.

Image credit: Kamila Figura

The Agile methodology revolves around constant iterations, incremental steps, and prototypes. This means short development cycles each one of which results in a valuable fraction of product, complete and ready to go. As opposed to the physical product building approach where it’s more like an assembly line and the viability of the components can be visible after the final assembly, incremental development delivers working functionality within a fixed time.

A product can therefore go through several iterations within an increment and have several increments before the product is complete.

Because of the specifics of the digital product demand, successful software entrepreneurship has to be sensitive to the transient requirements of the market. The lifespan of a digital product today is as short as anything in the age of ADD and just being innovative and developing fast is not enough. The ability to pivot the digital product close to the launch is what makes the product valuable manifold.

“Companies who realize that the ultimate customer value is delivered at point-of-sale, not point-of-plan, will have a huge competitive advantage.” – Jim Highsmith

All the above shaped a new paradigm of product development and raised a generation of digital entrepreneurs and the actual practitioners of digital production. The detachment from physical development has become increasingly evident once the beneficial principles of digital development were tested on tangible product development.

Agile frameworks for physical products

Despite the influence digital products have on our daily lives, they are nothing unless they are delivered to us by means of some physical media. In a way, physical production has been following the same path of automation, machines and AI running processes with the precision unavailable for humans, yet the underlying principle of physical product development remains the same – extensive planning.

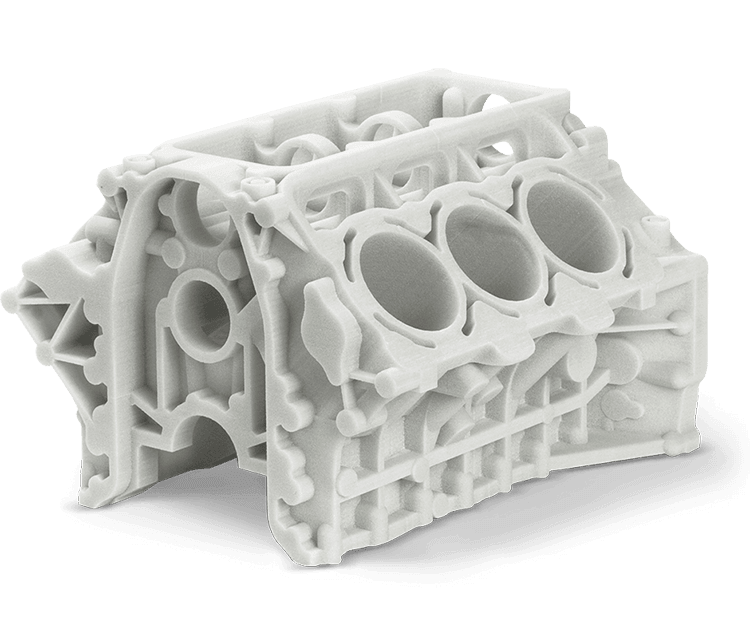

The first problem we faced building our wall gym timer was the lack of planning. We 3D-printed the body only to realize we did not need a half of it. Now imagine we’ve printed 10 000 of those.

The price for a mistake or misjudgement on the early stages of physical production may result in the entire startup failure.

Needless to say, the attempts to apply digital production methodologies that have proven to be extremely effective for tangible goods production are underway to this day. The mindset of execution instead of prediction started to make sense once the digital product expectation phase imprinted on the physical product development rates.

In other words, we expect new electronics, devices, cars, and houses to emerge just as apps do.

On one hand, this pushes the industry to progress in technology, resource policy, and marketing. On the other, it leaves only so much time for conceptualizing, testing, and fine-tuning the product. Agile is a huge layer of multiple hybrid frameworks emphasizing different principles. Next, we’ll take a look at how those frameworks can potentially be used for physical product development.

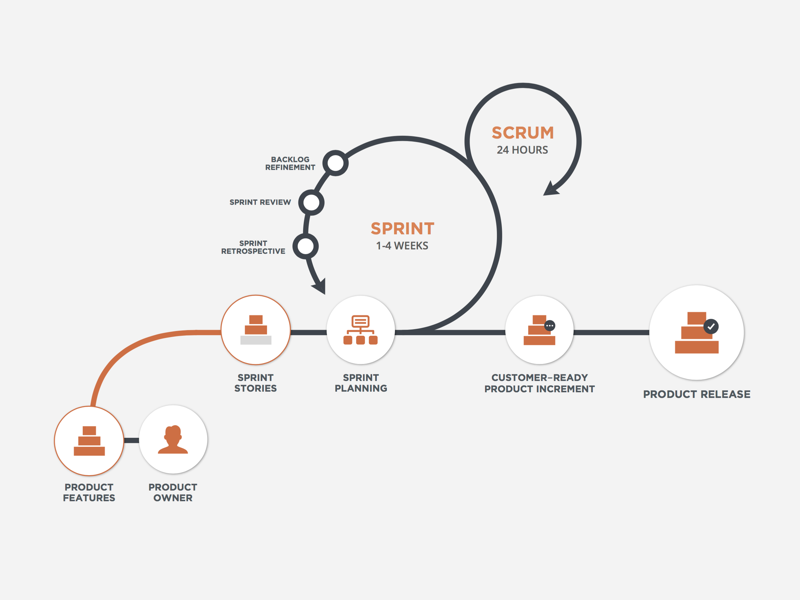

Scrum

One of the first attempts to shift the focus of physical production to an execution and result approach was the introduction of the Scrum methodology. In its core, Scrum emphasizes data gathering before decisions, iterations through communication, and increments.

Scrum runs on self-organizing teams and sprints during which the tasks have to be accomplished regardless of the big picture.

Phases of Scrum:

- Research sprints

- Architecture sprints

- Design/Development sprints

- Distribution sprints

Image credit: Bryttni Wolfe

With all the above, Scrum is capable of ministering a physical product development. It gives the product a chance to excel on multiple levels while leaving an opportunity for a pivot if required.

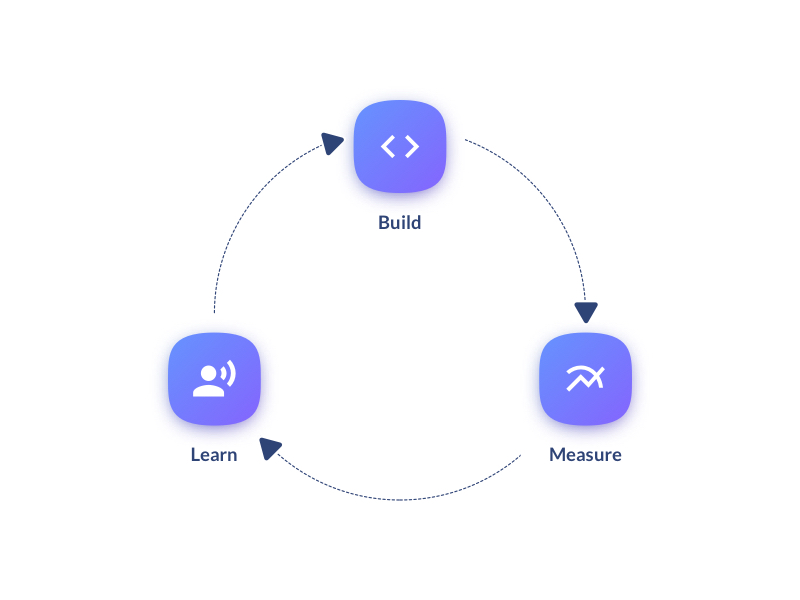

Lean

One of the most intense features of the digital startup realm is the development of the “conditions of extreme uncertainty.” More often than not, digital startup owners can’t afford to be extravagant, thus they require a different, DIY-ish approach to building. Lean Startup is one of the agile frameworks created just for that. Lean is all about giving it a shot and bailing out if it doesn’t work out.

It doesn’t matter which scarcity you are dealing with: knowledge, money, talent – regardless of the circumstances, you are not supposed to suffer even in the worst case scenario.

The core of Lean Startup is building an MVP which you can measure the success of the idea by, learn from, and then decide whether to keep going. It is even said that Toyota’s production model was inspired by the same agile principles that form the Lean methodology.

Phases of Lean:

- Build MVP

- Measure MVP

- Learn from MVP

Image credit: Lennart Brandt

To some extent lean can be used for physical product development. I’d say for a device or a hardware startup

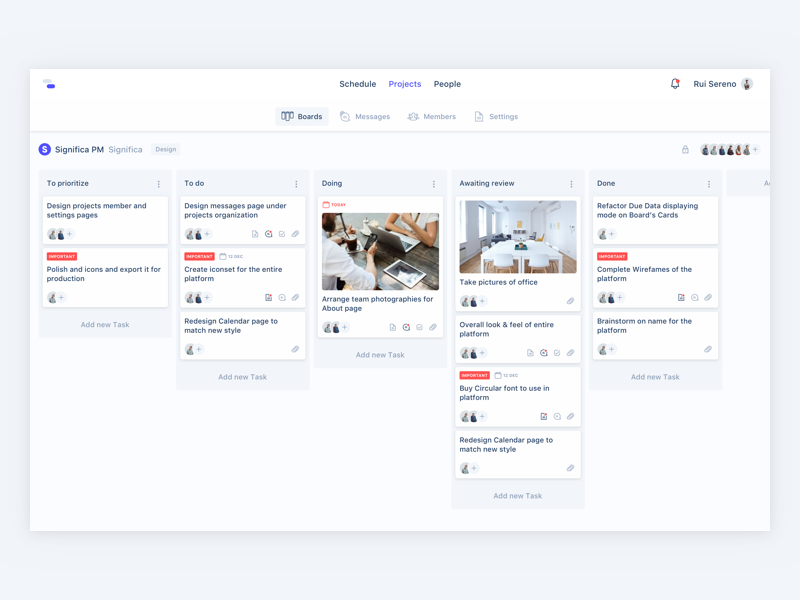

Kanban

What Toyota has done is they perfected the Lean framework so it would be relevant for their needs. They used their data on market demand to redesign their workflow from the “work-in-progress” mode to the “just-in-time” production.

In a nutshell, Kanban is a no-bullshit approach to performing tasks. If something/someone prevents the task from being done, it has to be dealt with right away.

In order to operate within the Kanban framework, the production has to follow a few improvement principles, among which are:

- Visibility

- Strict limitations

- Unbreakable rules

- Deep analysis

What makes Kanban fully applicable for physical production is its supplemental nature. Using the Kanban mindset can help streamline any process really.

Image credit: Rui Sereno

Design Thinking

This might not be a full-blown methodology, but in the digital sphere, Design Thinking is a proven successful approach to building customer-based products. The proponents of Design Thinking put the human perception of a product ahead of its predicted business value, believing that business value is the result of the aesthetic impression a product makes.

A product created after Design Thinking is human-centric, bold, innovative yet intuitive and familiar, and comprehensible.

To be design-driven a product has to be:

- Empathic and user-aware

- Helpful

- Contemplated

- Probe-tested

The understanding of users you develop while working in the Design thinking mode is guaranteed to give you the value you are looking for. However, it requires a great deal of creativity, courage, and is merely impossible if you are dealing with a high-impact physical product with all sorts of institutional limitations on it.

Image credit: Sofy Dubinska

Flexible Product Development

One of the most feared outcomes of a physical production is becoming obsolete either right after the launch or worse, before the launch. This might happen either because of the nature of market demand these days, or because of the overdue production, or the general inability to pivot the product early enough so that it could stay in the loop.

Flexible Product Development (FPD) was created to allow developers to retain control of the product’s final version. In the digital realm, this is reached through smaller iterations with results tested in the customer environment. The final product consists of the increments which in their turn consist of those customer-rated iterations.

FPD is based on the modular structure of the product, experiments and simulations, design systems, and versatile process.

The key skill in FPD is the ability to change the entire game plan based on the data received from the market. In this context, being sensitive to the needs of the market, capable of providing quick and presently topical designs, and contributing to the team effort are the most important aspects.

Even though physical production is hardly flexible, more and more technologies emerge to make production sites as versatile as possible. Flexible mindset makes you look for the hardware solutions and facilities to correspond to that flexibility.

Image credit: henrique barone

The ambiguity

As we know, the principles of Agile development contributed to the unprecedented rise of digital technologies in the past couple of decades. The current of the new reality was so strong, it washed away a lot of the solid multi-billion industries that have existed for ages. We’ve taken the digital representation of our lives to such heights, we have a hard time separating ourselves from it.

The knowledge of the entire humanity is in the phone in our pocket. With that said, the knowledge it takes to build that phone is hidden from our consumer eyes.

We’ve learned that anybody can make it in the digital universe. All you need is a vision and the guts to push through it. We know the front side and we love it. Every IT person wants to work for Apple but nobody wants to work at an Apple plant.

As the result, the hardware and tangible product industry have directed its eyes on the way they do it in digital. After a decade of different approaches, restructuring, reorganizing, and rebuilding the production methods, here’s what they’ve come to:

- Physical and hardware production can’t just be segmented wherever you want.

- The production equipment does not tend to change a lot, which handicaps product development.

- If you actually keep changing things, this will eventually drain the budget and you’ll never end up producing anything but analytics.

Instead of blindly following the digital path, physical production has to focus on the benefits of Agile development which constitutes 90% of digital product development, and apply them responsibly.

While the core values of Agile are fully applicable to hardware production philosophy, it is still a question of dispute whether introducing the Agile principles is worth it. At the root of this dispute lies the fundamentally different conditions under which digital and physical products are built and used. Thus, a different intensity and different consequences.

We are yet to see how the digital approaches to building products will manifest themselves in tangible goods. One thing is sure, if we witness those, we will also witness a major social and economic formation change.

Image credit: James Tabiner

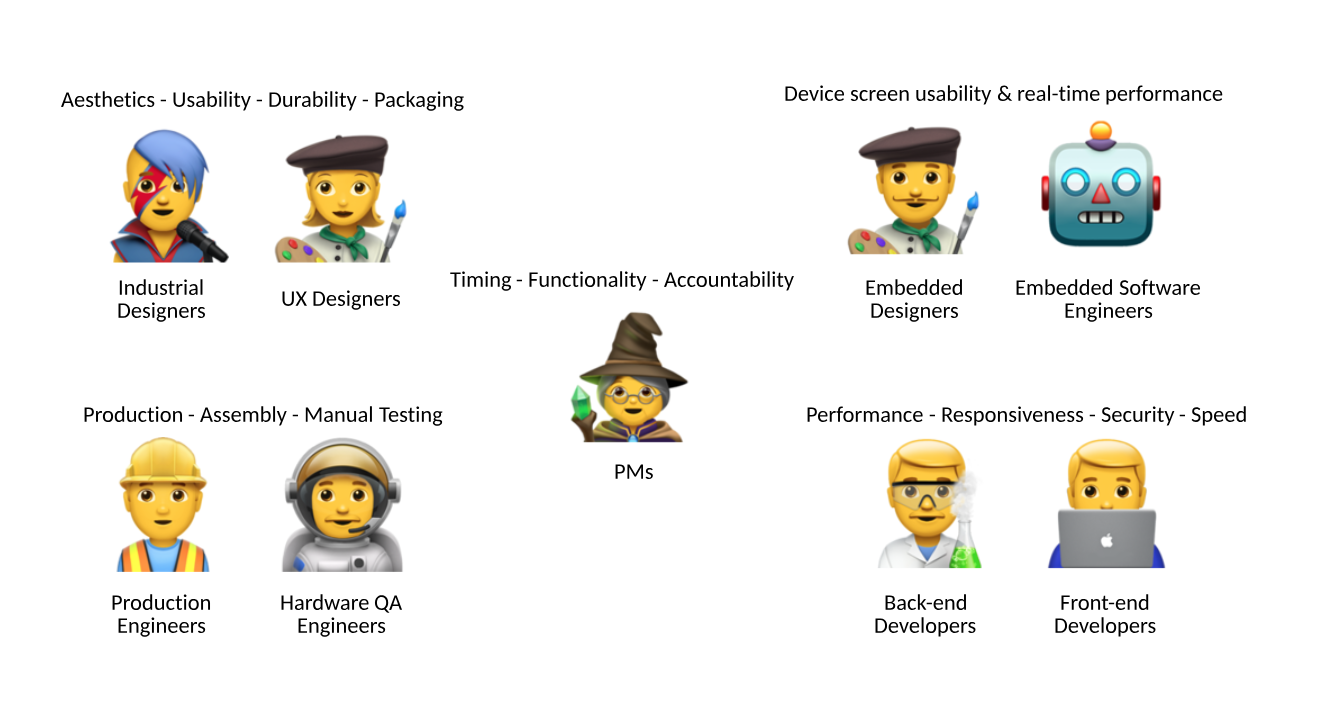

The roles, the people, and the process

Let’s go back to entertaining the idea of digital designers and developers using their expertise to build a physical product. In the digital realm, it’s rare these days that a company would only concentrate on one aspect like UI design or front-end development, or back-end development. Instead, companies look to engage full-stack developers in both web and mobile, as well as experience and interface designers along with writers to make products not only functional but also appealing.

With that said, physical product development or Internet of Things production requires a certain synergy of industrial design/development specialists, and digital pros.

Let’s consider the roles that a hardware project might require. We’ll make it even harder by assuming the generic product is hardware but also smart. Either, as part of the Internet of Things movement or a hi-tech device of some sort. Along with the roles, we’ll take a look at the scope of involvement and skills required for the roles in such a startup.

This should all be taken with a grain of salt as every project is unique and in a lot of ways depends on the team’s ability to create a workflow that utilizes its fortes and looks to improve the weaknesses.

Product leadership

Most digital companies are used to dealing with distributed environments, overseas offices, and international teams, so separating the workflow between the production facility and the office should not be a problem. However, the work of the management team multiplies with the involvement of the physical variables. You have to deal with the suppliers, regulations, and federal standards.

The lifespan of a physical product is generally longer than that of a digital one. A physical product only starts when it’s purchased, whereas a digital project is done upon the release.

Depending on the methodology selected – traditional or Agile, the workflow has to consider the limitations and risks at every step of production and work towards the reduction of these risks. Managing the two types of projects can be referred to as piloting a transport.

Running a digital product is like flying a plane. The ride is short, exciting, and manoeuvrable. Running a physical product is like steering a train. Slow acceleration, not a whole lot of nimbleness, but a way longer journey and plenty of useful space.

Design and production

Designing a digital product is a trade-off between functionality and delightfulness. Digital designers are constantly in search of a better experience, hence more value. Tangible product design has to deal with more aspects like environmental friendliness, a context of usage, safety, and etc.

At the same time, physical prototyping is much more beneficial in terms of funding, and visual assessment. The value of a digital product unfolds much later into development, while physical prototypes can be tested early.

Besides the screens and interaction design, building a physical product requires knowledge of physics, structural performance of materials, and construction principles. Knowledge of ergonomics is also a prerequisite, along with the understanding of the assembly tools and specifics.

Image credit: 3dprintdirect

Backend systems development and embedded development have to follow not only the business logic of a product but showcase the required degree of security and safety. There are nationwide standards for electronics that the device has to follow.

A great challenge is to not get caught in the whirlwind of business and industrial requirements, retain ethics, and find ways to improve the product while staying customer-friendly.

. . .

All in all, everything about a physical product is a rathole of unknown challenges. Manufacturing the product, having it tested, and then distributed across the country or worldwide, all present a bunch of problems and opportunities.

Despite a huge amount of differences, physical product development can take a lot from the digital production and vice versa. For example, we are yet to find which methodology would become the successor of the traditional waterfall model for tangible product delivery. There is something the digital industry can learn from physical production, risk assessment in particular, or multi-level operation and product localization throughout different national standards and technological environments.

Even though our sports timer production is far from being over, we can at least get a first-hand experience and perhaps contribute to the growth, even though such an insignificant input as this article. Peace.